Home > Products > CFA Auger Drill Pipe > China Factory Price High Speed Auger Drill Rod/Spiral/Pipe/Single Thread and Thread Twist Drill Rod for Coal Mining

China Factory Price High Speed Auger Drill Rod/Spiral/Pipe/Single Thread and Thread Twist Drill Rod for Coal Mining

- China

- T/T L/C PayPal D/P Western Union

- 7 days

You May Like

-

Large Diameter Spiral Drill Pipe for Slag Removal and Deep Hole Drilling Drill Pipe

-

Mine Exploring Twist Drill Rod Auger Spiral Geological Drill Pipe Price

-

Cheap Price Auger Drill Rod and Spiral Drill Pipes Auger Stem/ Helix Screw Drilling Rod

-

CFA Drilling Tools Continuous Flight Augers for Rotary Drilling Rig

-

Cfa Digging Tools Screw Flight Auger for Pile Making Machine

-

Interlocking Kelly Bar for Depth Drilling Bored Piling Construction

Product Details

| Condition | New | Application | Other, Construction machinery parts | |

| Type | Other, CFA Drilling Tools |

Product Description

Robot welding

Introduction

In the realm of coal mining, the efficiency and reliability of equipment are of utmost importance. Our China factory - produced high - speed auger drill rods are engineered to meet the demanding needs of the coal mining industry. These drill rods come in various forms such as spiral, pipe, single - thread, and thread twist designs, offering a wide range of options to suit different coal mining scenarios.

Product Features

- High - Speed Performance

- Our drill rods are designed for high - speed operation. The advanced manufacturing process ensures a smooth rotation, which significantly reduces the time required for drilling. This high - speed capability allows coal mining operations to progress at a much faster pace, increasing overall productivity. For example, in a large - scale coal mine, using our high - speed drill rods can lead to a notable reduction in the time taken to reach the coal seams, thereby saving both time and labor costs.

- Multiple Design Options

- Spiral Design: The spiral drill rods are excellent for removing cuttings efficiently. The spiral shape helps in carrying the coal cuttings out of the borehole as the drill rod rotates. This design minimizes the risk of blockages in the borehole, ensuring continuous and smooth drilling operations.

- Pipe Design: The pipe - type drill rods are known for their strength and durability. They can withstand high - pressure conditions during drilling, making them suitable for deep - coal mining operations. The thick - walled pipe structure provides additional support, preventing the drill rod from bending or breaking under extreme stress.

- Single - Thread Design: Single - thread drill rods offer simplicity and reliability. They are easy to operate and maintain, making them a popular choice for small - to - medium - sized coal mines. The single - thread design also provides good torque transfer, ensuring effective drilling.

- Thread Twist Design: The thread twist drill rods are designed to optimize the cutting action. The unique twist pattern helps in better penetration into the coal seams, reducing the energy consumption during drilling. This design is particularly useful in hard - coal mining areas where a more powerful cutting force is required.

- Factory - Direct Pricing

- Being a factory - direct product, our high - speed auger drill rods are offered at highly competitive prices. By eliminating the middlemen, we can pass on the cost savings to our customers. This means that coal mining companies can acquire high - quality drill rods at a lower cost, improving their profit margins. Moreover, our factory has strict quality control measures in place, ensuring that the low price does not compromise on the quality of the drill rods.

- Superior Material Quality

- We use high - grade steel materials in the manufacturing of our drill rods. These materials are carefully selected for their strength, toughness, and wear - resistance properties. The high - quality steel ensures that the drill rods can withstand the harsh conditions of coal mining, such as abrasion from coal particles and high - pressure drilling environments. This results in a longer service life for the drill rods, reducing the frequency of replacements and associated costs.

- Precision Manufacturing

- Our drill rods are manufactured with high precision. The threads are accurately machined to ensure a perfect fit between different drill rod sections. This precision also helps in maintaining the alignment of the drill rod during operation, reducing the risk of misalignment and potential damage to the drilling equipment. Additionally, the precise manufacturing process ensures that the drill rods have consistent performance, which is crucial for reliable coal mining operations.

Application Scenarios

These high - speed auger drill rods are suitable for a wide range of coal mining applications. They can be used in both surface and underground coal mines. In surface coal mines, the drill rods can be used for exploratory drilling to identify the location and quality of coal seams. In underground coal mines, they are essential for creating boreholes for ventilation, drainage, and coal extraction. Whether it is a small - scale coal mining operation or a large - scale industrial project, our drill rods can provide the necessary performance and reliability.

Technical Specifications

The drill rods are available in various diameters and lengths to meet different coal mining requirements. The diameters typically range from [specific diameter range] and the lengths can be customized according to the customer's needs. The surface of the drill rods is treated with anti - corrosion coatings to enhance their resistance to the harsh coal - mining environment. The threads are designed to meet international standards, ensuring compatibility with different types of drilling equipment.

Quality Assurance

Our high - speed auger drill rods are subject to rigorous quality testing before leaving the factory. We conduct tests such as hardness testing, tensile strength testing, and non - destructive testing to ensure that each drill rod meets the highest quality standards. Our quality control team monitors every step of the manufacturing process, from material selection to the final product inspection. This strict quality assurance process gives our customers the confidence that they are purchasing a reliable and high - performance product.

After - Sales Service

We are committed to providing excellent after - sales service to our customers. Our technical support team is available 24/7 to answer any questions or provide assistance regarding the use and maintenance of the drill rods. In case of any issues, we can quickly provide replacement parts or offer on - site technical support. We also offer training programs for coal mining operators to ensure that they can make the most of our high - speed auger drill rods.

In conclusion, our China factory - produced high - speed auger drill rods are a top - choice for coal mining operations. With their high - speed performance, multiple design options, factory - direct pricing, superior material quality, and excellent after - sales service, they can significantly enhance the efficiency and profitability of coal mining projects.

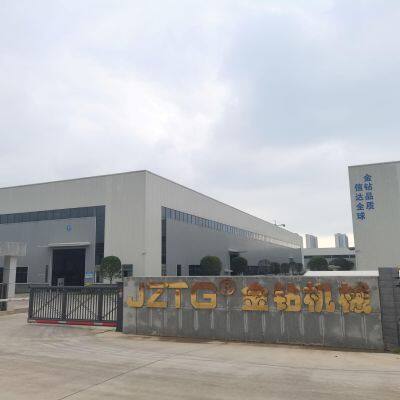

Company Profile

Changsha Mingyi Machinery Equipment Co.,Ltd pecialized in pile driving solutions with our own production base , with over 33600 square meters and annual ouput of 5,000 unites. Our factory locates in Hunan province which is in the center of China famous for heavy equipment manufacturers. MINGYI is committed to manufacture and supply most reliable and highest cost-performance products for piling works including Kelly Bars, Drilling Tools, Drilling teeth, Double and Single Wall Casing, Roller Bits, ect . We are keep 300-400 pieces in stock to ensure quiclky delivery. Our production process utilized advanced equipment,inlcuding 30kw laser cutting machines , high-power shot blasting machine ,beveling machine, and a complete assembly line with riveting tools ,we also employ professional pain boothss and automated welding robot syssterms to ensure every drilling bucket meets the highesst standards of quality and durability . our professional team is ready to support you with customizable designs and excellent after-sales service!

Contact Us

- Changsha Mingyi Machinery Equipment Co., Ltd.

- Contact namezhu Chat Now

- Address1917, Building 18, Contemporary Square, No. 288 Kaiyuan East Road, Xingsha Street, Changsha County, Changsha, Hunan

Product Categories

| Auger Bit | CFA Auger Drill Pipe | Core Barrel | Drilling Bucket |

| Kelly Bar | Spare Part | Drill Rig Swivel |

New Products

-

Heavy-Duty Interlocking Kelly Bars for Robust Construction Projects

-

Interlocking Kelly Bar Matched Zoomlion Drilling Rig Machine for Construction/Mining/Civil Engineering

-

Heavy Construction Equipment Spare Parts Interlocking Kelly Bar for Soilmec Piling Rig

-

Cost Effective Friction Kelly Bar for Efficient Piling Construction Foundation Drilling

-

Yellow Foundation Drilling Tools, Construction Friction or Interlocking Type Kelly Bar Rotary Piling Rig Parts

-

Drill Rig Friction Rotary Drilling Interlocking Kelly Bar

-

Rotary Rig Interlocking Kelly Bar Foundation Drilling Equipment

-

Rotary Drilling Rig Spare Parts Interlocking and Friction Kelly Bar for Sale

-

China Piling Rig Rotary High Quality Kelly Bar Can Customized

-

Kelly Bar for Rotary Drilling Rig Interlocking/Friction

-

Rotary Rig Machine Interlocking Kelly Bar Friction Kelly Bar for Foundation Construction

-

Foundation Piling Machine Accessory Part Rotary Drilling Rig Kelly Bar

-

Customizable All-Brand Rotary Rig Drilling Spare Parts Interlocking Kelly Bar

-

Best Sale Kelly Bar for Hydraulic Piling Machine Rotary Drilling Rig

-

Rotary Digging/Drilling Machine/Bauer Piling Rig Spare Parts Kelly Bar

-

Rotary Drilling Rig Interlocking/Friction Kelly Bar

-

Kelly Bar High Wear Resistance, Custom-Made, Specifically Designed for Rotary Drilling Rigs

-

Friction Kelly Bar for Rotary Drilling Rig Can Customized

-

Customized Drilling Tool Kelly Bar Strips and Locks for Rotary Drilling

-

Bullet Tooth Auger Teeth Drilling Teeth Rock Tools Core Barrel Cutter Tooth Factory Price

-

Factory Supply High Quality Bauer Standard Bullet Teeth for Rotary Drilling Rig Auger Buckets

-

High Performance Drilling Tools Parts Carbide Drill Bits Spherical Button for Anchor Cable Holes

-

Promotion Special Offer Construction Machinery Parts-Drilling Tools and Bucket for Construction Machine

-

OEM/ODM Bullet Teeth for Bore Pile Replacement Hard Rock Ripper Tooth Tipped Cutting Rock Quarrying Drilling Bullet Teeth

Popular Searches

- Machine Equipment

- rock drill

- construction equipment

- mining equipment

- Drilling Tool

- Petroleum Equipment

- rotary drilling rig

- water well drilling rig

- Heavy Equipment

- core drilling rig

- drilling machinery

- water well drilling equipment

- Oil Drilling Equipment

- drilling pump

- rotary drilling equipment

- Drill Equipment

- rock drilling equipment

- piling equipment

- rock drilling bits

- Drill Rig Equipment

- hydraulic rotary drilling

- rotary drilling system

- rotary drilling series

- engineering geological exploration drill

- mud rotary drilling

- cutting tool

- rock drill

- pile driver

- drill bits

- Drilling Tool

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Engineering & Construction Machinery Parts

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhu

Hi there! Welcome to my shop. Let me know if you have any questions.

zhu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile